Description

Description

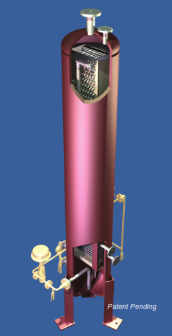

SME offers a unique JT Dew Point Control system that combines all of the heat exchanger streams into one heating coil, which is a fin and tube type heat exchanger. The entire fuel gas conditioning unit and the controls are installed in a single vessel, eliminating the need for interconnecting piping. Another unique feature of this unit is the ability to handle separated cold liquids. This DPC is beneficial in applications where space, weight and a small footprint are important, such as off-shore oil platforms. Produced gas near the hydrocarbon dew point must often be conditioned to lower the content of the high molecular weight components of the gas prior to introduction into a pipeline.

A dew point conditioning unit separates and removes the propane & “heavy” hydrocarbons to meet the pipeline requirements. The pressure drop of the inlet gas from pipeline pressure provides the necessary refrigeration so that no moving parts are typically required. Residue recompression is typically required to send the residue gas to pipeline. As an alternate, an external refrigeration system can be supplied so that pressure drop thru the system is minimized; thus no recompression is required. Our flexible designs allow for all the refrigeration to come from the JT expansion, or all of the refrigeration from an external source, or a combination of JT expansion and external refrigeration. A variety of standard configurations and sizes are available to meet most applications.

Specs

Typical Applications: Gas gathering and pipeline dew point control

Min Temp: -260°F

Max Temp: 150°F

Max Pressure: 1440 psi

Design Codes Available: ASME

Documentation

Product Brochure: Download PDF